Starting on an untested, poorly documented printer with ABS may have been a little ambitious, (or sadistic) but my calibration efforts have finally started to pay off. One of the biggest problems I ran into was some odd behavior in the yellow ABS I was using. I ran into this strange issue where pauses of about 90 seconds or longer would cause a horrible jam and I'd have to take apart the whole hot end. The filament was a little oblong, but even correcting for that I still ran into jamming issues. I switched hot ends, with little luck. Switching to a different color made all the difference, even though its from the same manufacturer. Although brown isn't the most attractive color, it prints consistently and has made flow rate and extrusion width calibration much easier.

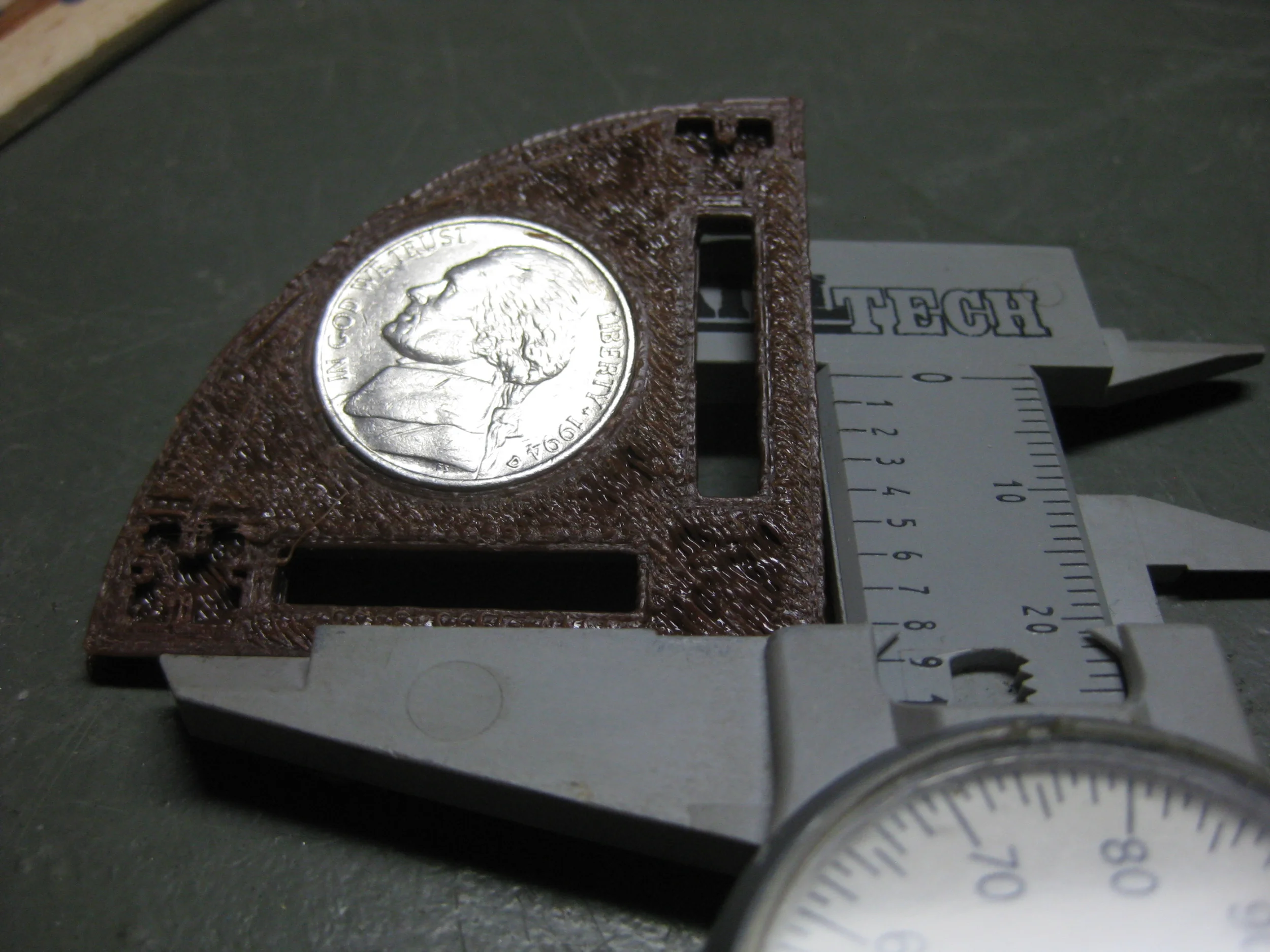

Another necessary calibration task was properly orienting the x-y travel of the gantry to be as parallel as possible to the print bed. Using calipers, I got the toolhead plane to within about 10 thousandths of parallel which should be ok for our purposes.

Between these two operations, the RPM can achieve about 95-99% trueness on the nickel calibrator found here. I still have a long way to go, but its a good start.